新闻中心

新闻中心

- 解决罗茨真空泵噪音大的有效方法

- 探秘罗茨风机:如何正确安装罗茨风机来**鱼塘水质?

- 探究罗茨风机客户常见咨询问题解析客户关注的核心问题

- 河道在城乡发挥着行洪、排涝、灌溉、生态调节、美化环境等重要作

- 问:膜微生物处理水污染技术有什么特性?

- 问:我们是一个小型的污水处理厂,选用什么样的风机曝气好啊?

- 养殖用罗茨鼓风机的优点总结

- 罗茨真空泵没进水里,走电问题是造成烧毁的主要素之一

- 罗茨鼓风机维护的综合检查方法

- **罗茨风机风压的方法

- 瑞柘罗茨鼓风机原理与结构简介

- 问:河道生态治理技术有几种?分别有什么优缺点啊?

- 江浙沪罗茨鼓风机供应商简介

- 污水处理厂运营管理方案(下)

- 污水处理厂运营管理方案(上)

联系我们

手机:15900463963

电话:400-155-8689

邮箱:

地址:江苏省苏州市昆山市

推荐产品

行业新闻

真空泵在烯酮生产中的应用

- 作者:超级管理员

- 发布时间:2022-05-11

- 点击:1408

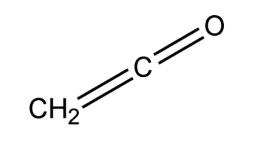

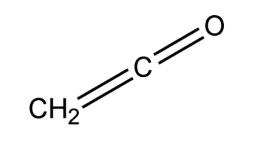

乙烯酮是一种**化合物,化学式为 C2H2O。它是*简单的乙烯酮。它在室温下是一种有毒气体,非常不稳定。它只能在低温下储存。在 0 °C 时,会发生聚合反应。乙烯酮是一种无色气体;有类似氯和醋酸酐的刺激性气味;它有毒,吸入后会引起严重的头痛;可液化成无色液体;熔点-151°C,沸点-56°C。

乙烯酮是一种优良的酰化试剂,是**合成中不可缺少的中间体之一。从乙烯酮、双乙烯酮开始,可开发出几十个系列的精细化学品,可广泛应用于医药、农药、染料等领域。、**颜料、香料、食品和饲料添加剂、工程塑料和合成纤维等领域,其开发和应用前景十分广阔。特别是近年来,随着乙烯酮氯化合成氯乙酰氯新工艺的开发以及乙酰丙酮、山梨酸等其他下游产品的开发,乙烯酮一直处于紧缺状态。

有许多制备乙烯酮的方法。以醋酸为原料,在负压下催化脱水是目前国内外制备乙烯酮类产品的主要生产方法。乙烯酮生产采用安全、稳定、经济的液环真空泵。随着技术的不断进步,液环泵在乙烯酮生产中的应用得到进一步优化。

裂解:裂解炉按操作程序加热至800℃左右恒温2小时后,将冰醋酸配成95%溶液,加入汽化器蒸发成醋酸蒸汽,加入预热炉内与催化剂磷酸三乙酯一起预热。进入裂解炉后,裂解成乙烯酮气体。

分离:乙烯酮气体、未裂解的乙酸蒸气和裂解炉产生的水蒸气混合气体依次进入**级和第二级套管冷凝器冷凝,稀乙酸从**级和第二级分离出来。第二级分离器。,从二级分离器出来的气体进入三级列管冷凝器进一步冷凝,分离出稀醋酸,然后气体通过真空泵吸收塔中产生的各种后续产物双烯酮。节或其他节产生的乙烯酮。醋酸浓缩后涂抹。

在乙烯酮裂解分离过程中,液环泵起着重要作用,液环泵是等温压缩过程。由于乙烯酮极不稳定的性质,大大减少了材料的浪费。使用液环泵对生产更安全,大大避免了冷却盐水进入系统的危险,大大减少了真空泵突然故障引起的系统真空度突然下降甚至乙烯酮泄漏;此外,液环泵更环保,噪音低,污染小,无需经常维护,减少乙烯酮外排。

瑞柘环保生产的真空泵泵送能力从27m3/h到60,000 m3/h。2BE1和2BE3系列常用于生产乙烯酮。具体选型和报价请联系我们的专业销售团队。

Ketene is an organic compound with a chemical formula of C2H2O. It is the simplest ketene. It is a toxic gas at room temperature and is very unstable. It can only be stored at low temperature. At 0 °C, a polymerization reaction can occur. Ketene is a colorless gas; it has a pungent odor similar to chlorine and acetic anhydride; it is toxic and can cause severe headaches after inhalation; it can be liquefied into a colorless liquid; melting point -151°C, boiling point -56°C.

Ketene is an excellent acylating reagent and one of the indispensable intermediates in organic synthesis. Starting from ketene and diketene, dozens of series of fine chemicals can be developed, which can be widely used in medicine, pesticides and dyes. , organic pigments, spices, food and feed additives, engineering plastics and synthetic fibers and other fields, its development and application prospects are very broad. Especially in recent years, with the development of a new process for synthesizing chloroacetyl chloride by chlorination of ketene and the development of other downstream products such as acetylacetone and sorbic acid, ketene has been in short supply.

There are many methods for preparing ketene. Taking acetic acid as raw material and catalyzing and dehydrating under negative pressure are the main production methods for preparing ketene products at home and abroad. Safe, stable and economical liquid ring vacuum pump is used in the production of ketene. With the continuous progress of technology, the application of liquid ring pump in ketene production has been further optimized.

Cracking: After heating the cracking furnace to a constant temperature of about 800C for 2 hours according to the operating procedures, glacial acetic acid was made into a 95% solution, added to the vaporizer to evaporate into acetic acid vapor, and added to the preheating furnace together with the catalyst triethyl phosphate to preheat. After entering the cracking furnace, cracked into ketene gas.

Separation: The mixed gas of ketene gas, uncracked acetic acid vapor and generated water vapor from the cracking furnace enters the first-stage and second-stage casing condensers for condensing in turn, and the dilute acetic acid is separated from the first-stage and second-stage separators. , the gas from the two-stage separator enters the three-stage tube condenser for further condensation, and the dilute acetic acid is separated, and then the gas is passed through a vacuum pump to absorb various follow-up products of diketene produced in the section or ketene produced in other sections. Apply after acetic acid concentration.

In the process of cracking and separating ketene, the liquid ring pump plays an important role, and the liquid ring pump is an isothermal compression process. Due to the extremely unstable nature of ketene, the waste of materials is greatly reduced. The use of liquid ring pump is safer for production, which greatly avoids the danger of cooling brine entering the system, and greatly reduces the sudden drop of vacuum in the system or even the leakage of ketene caused by the sudden failure of the vacuum pump; in addition, the liquid ring pump is more environmentally friendly, The noise is low, the pollution is small, and frequent maintenance is not required, which reduces the efflux of ketene.

The vacuum pumping capacity of Ruizhe environmental protection production ranges from 27m3 / h to 60000 m3 / h. 2BE1 and 2BE3 series are commonly used in the production of vinyl ketones. Please contact our professional sales team for specific selection and quotation.

![鲁氏罗茨风机-三叶罗茨鼓风机厂家-沉水式鼓风机-[瑞柘环保]](/static/upload/image/20220309/1646805698217314.png)

客服QQ

客服QQ